Project planning

The main focus is on trust, expertise and transparency in project planning. If required, we can look after the entire planning and implementation of a project – including the purchasing of all materials. As a customer, you benefit from this purchasing optimisation to a special degree.

From the initial discussion to the completion of the project, you have a partner who you can put trust completely. This also includes project stages such as risk assessment and risk analysis, cost optimisation and part list management. We will support you in optimising your supply chain and your value creation.

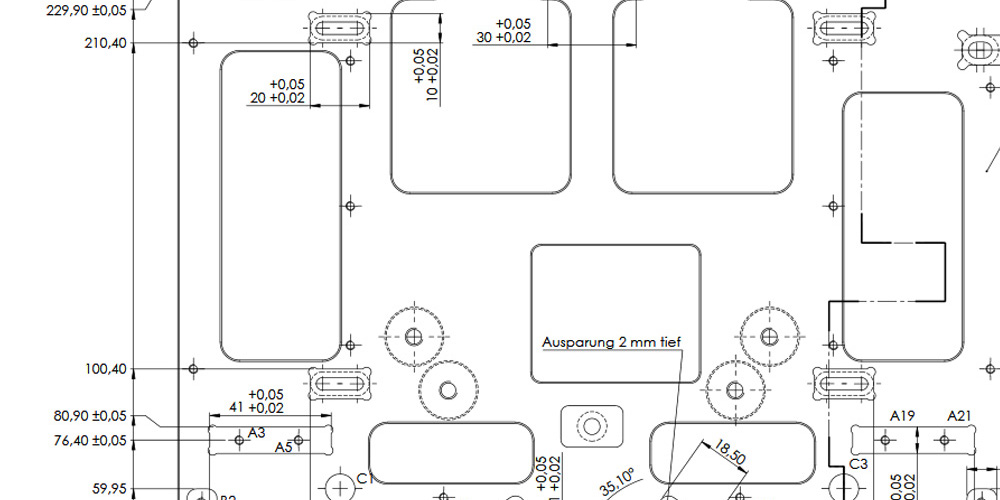

Design

2D/3D design is carried out using the Solid Edge and Solid Works programs. If required, our powerful design team will plan and design individual parts, assemblies or entire systems from prototype to high-end product.

The data that we receive from our customers can be taken over in a wide range of formats.

Development

Do you have an idea? Are you looking for a partner for developing a new product or optimising an existing product and making it viable for the future? Make use of our many years of experience, our current know-how and our high degree of solution expertise!

ELMAKO develops and manufactures prototypes, individual parts, small appliances, devices and machinery in different sizes and formats. In b2b projects we regard ourselves as part of a business relationship with a high degree of trustworthiness and commitment, and promote added value for everyone concerned in this way.

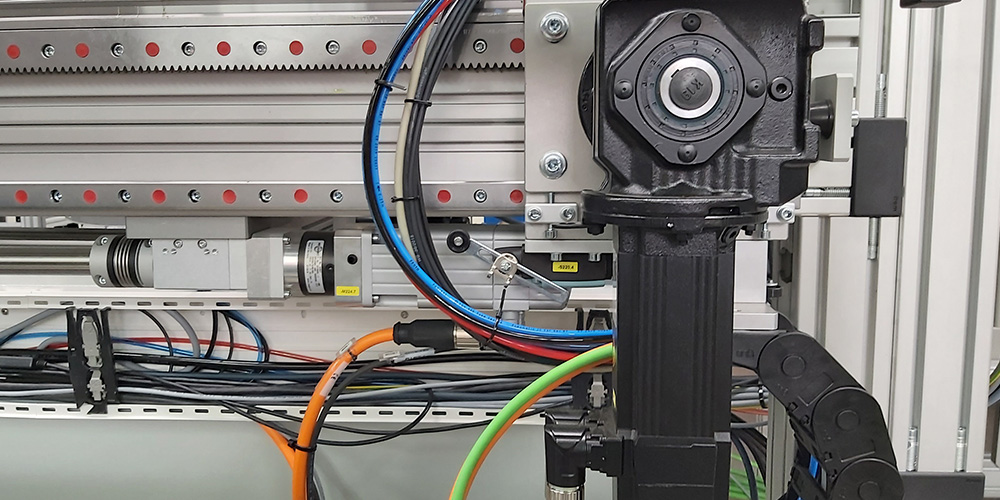

Electrical engineering + electronics

In the ELAMKO electrical engineering you will experience the “wiring of intelligence” – the performance range in the electronics and electrical engineering areas is also tremendous. The development and manufacturing of PCBs is also one of ELMAKO’s major strengths, as is the assembly, wiring and inspection of assemblies in accordance with specifications.

The realisation of finished solutions takes place in the project wiring area, according to plan and in accordance with the standards. This includes cable manufacturing and the wiring of plug-in units in accordance with requirements. The tools include ePlan P8, S5 PLC and S7 PLC. We provide our customers with project management using E-Plan P8 – the optimum display environment for electrical plans. Electrical PCBs are manufactured using EAGLE.

Automation

With us, our customers experience the “programming of intelligence” in the automation. The number of companies with expertise in this area is decreasing all the time. The re-programming of older devices or older systems in accordance with new, future-oriented standards is becoming increasingly important. The ELMAKO team provides the customer with more efficiency and value creation by converting production lines.

Programming of different PLC systems from Siemens (LOGO, S5, S7), OMRON (CPM1A to CS1D), Allan Bradley and other systems. Menu creation with HMI Touch Panel from Siemens and OMRON. Integration of Ethernet, Serial, DeviceNet, PROFIBUS-DP and CAN-Bus bus systems. User interface development and programming using LabVIEW for motor test benches.

The range of services also includes the repair and checking of systems and electrical systems.

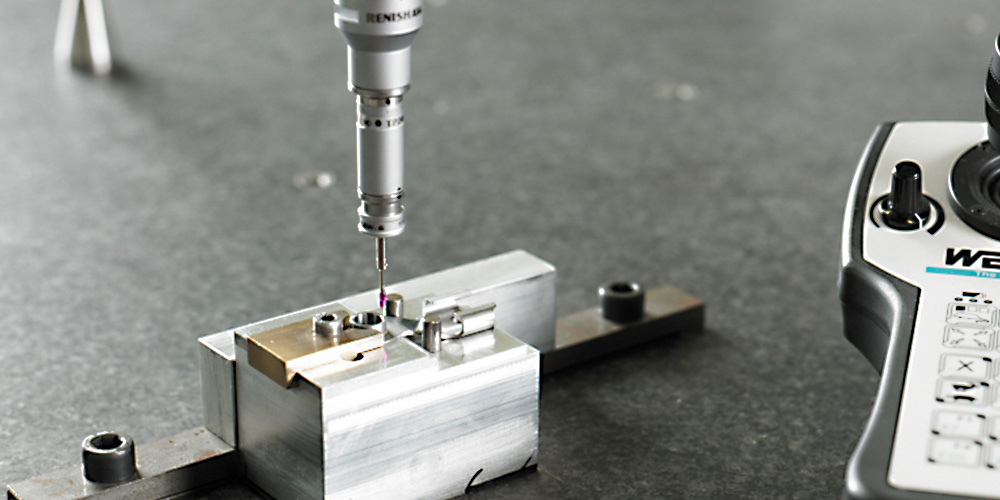

Testing

Automated testing has a high priority in quality assurance. We can plan, design, manufacture and program test systems for our customers.

The demand for ELMAKO’s testing competence is on the increase. The WENZEL machine, a 3D measuring machine, produces measurement reports for geometry. Do you want to know whether your product can withstand continuous operation? We can also perform the relevant testing here by means of our shift operation, and you receive all of the necessary information in the measurement report.

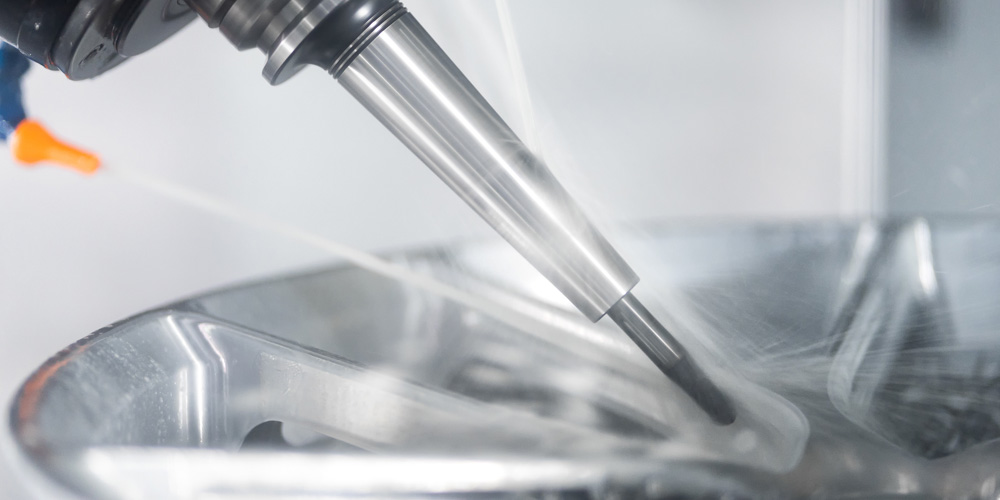

Manufacturing

ELMAKO is extremely well positioned and can reproduce an incredible number of manufacturing processes and special processes. In this way, customer requirements can also be introduced directly into the manufacturing during the process. Short distances, quick reaction times, flexible changes – this characterises ELMAKO in its manufacturing. We support our customers during the manufacturing processes with technical expert knowledge, which they can then incorporate in their processes and use, and therefore receive a high degree of added value.

We look after the entire supply chain through to the completion of the component. This also includes ensuring that our suppliers have the relevant certification.

The customer sends an inquiry – and we take care of the rest!

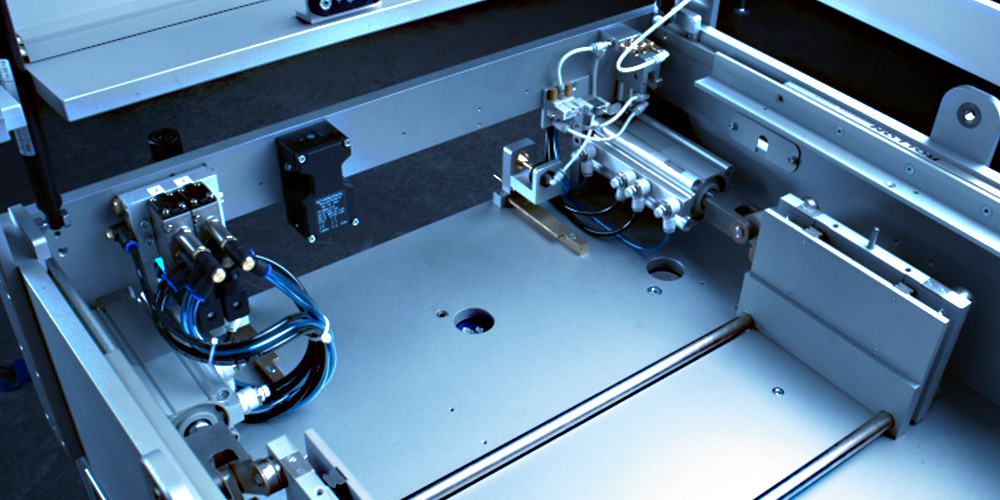

Assembly

The performance range of ELMAKO is also reflected in the assembly area: From planning and development to manufacturing and delivery, installation or commissioning on site and also personnel training if required.